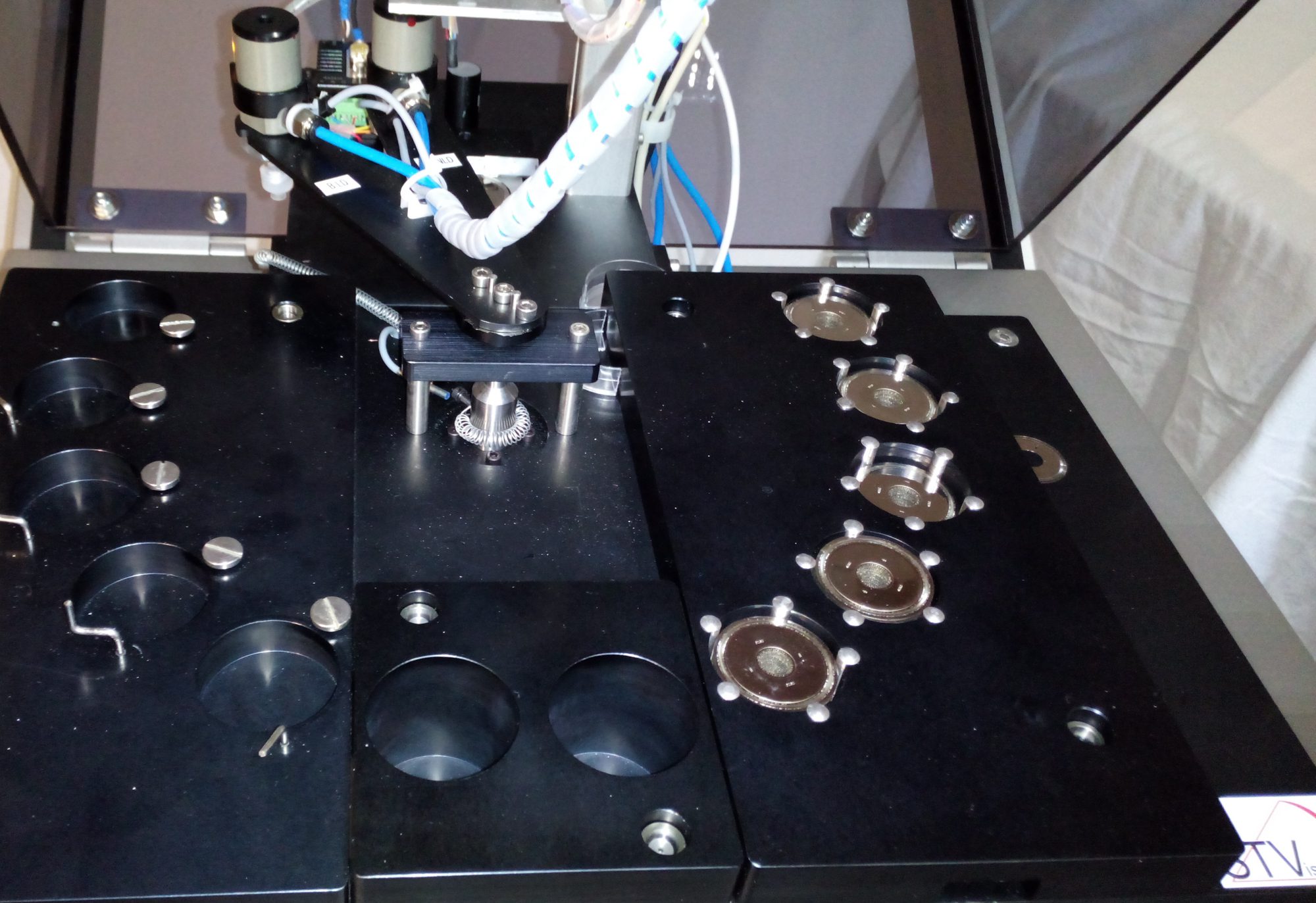

STB2 Illumination

STV introduces a new generation of illumination hard and software for industrial inspection. The system generates strobe light pulses for up to eight different illumination units. These may be top light, ring light, side light bars, or any other illumination device, based on LED technology. The LED switch very fast (in the range of microseconds), are free of maintenance and repair for many years. Today there are many high power LED on the market, which allow very bright intensity and extremely short pulses.

For example, STV uses this for illumination of inkjet nozzle plates in high speed continuous grab. Up to 15 high resolution images per sec are digitised, while the target is moving constantly. Holes as small as 4 micron diameter in the metal are measured with repeatability of around 0.1 micron. The camera is high resolution 1380 x 1040 pixel, and the motion has the speed of around 20 000 pixel per second. So within 50 microseconds, the target moves at about 1 pixel. And if you want a jitter free crisp image, the strobe light must be better than ¼ pixel diameter, so 12.5 microseconds.

The STB2 hardware allows programmable pulses between 2.5 nanoseconds and 15 milliseconds, spreading a range of almost six decades. Longer strobe pulses generate more light, of course, but the danger of motion effects increase.

The system generates up to eight independent outputs. They are all flashing with the same timing, same pulse length. But they can be programmed for individual brightness. Each pulse is current control logic. This assures that a definite amount of current is pumped into the LED device, independent of its internal voltage threshold. This assures very stable and identical brightness between channels.

Each channel output current is controlled via 14 bit D/A converter and high speed operational amplifier.

The system is an external USB programmable unit. Setup or chage of programming is within few msec USB speed. Strobe trigger is via camera signal, so the pulses are hardware synchronized to the camera image exposure. Multiple synchronous cameras are supported.

The system has unparalleled performance in pulse duration and light intensity stability. It is used to inspect inkjet nozzle holes at a magnification of 0.8 micon per pixel on the fly (moving target), and the measurement repeatability as well as long term stability of the illumination is as good as 0.1 micron hole diameter for any holes of diameter between 4 and 60 micron.

STV introduces the first software to vectorize CPU intense functions. The algorithms are splitted into balanced parallelthreads which are processed by the multiple CPU’s of the Core 2Duo or the new 4-CPU cores in parallel and enhances speed by up to a factor of 4! This is specially useful in the die surface inspections and applies on all types of imaging sensor.